"Engineered Wafer and Snack Lines"

Real Meanings of Complete Solution

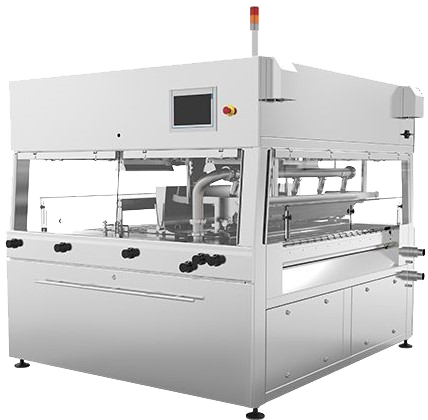

Chocolate/Barrier/Caramel Enrober

Twin heads model can enrobe two layers at once creating an extra thick chocolate layer or allowing for faster enrobing.

It is provided with two curtain boxes, two air-blower systems and two bottoming systems.

Perfect for large-scale productions up to 8 m/min operating speeds.

Single head model enrobers are suitable for full, half or bottom-coating of pralines, bars, pastries etc. with chocolate or chocolate compound, and for medium operating speeds of up to approx. 5 m/min.

Detachable lower section containing the chocolate service tank, enables rapid changeover and is suitable

FeaturesThe enrobers are suitable to enrobe chocolate, cocoline, barrier and caramel processing.

- Machine widths of 1000 to 1500 mmUniform coating of products

- Uniform coating of product surface

- Hygienic design with stainless steel surfaces for maximum cleanliness and ease of cleaning

- Advanced closed water system

- The enrobers are suitable to enrobe chocolate, cocoline, barrier and caramel processing.

- Slow-running, temperature-neutral chocolate pumps

- Blower operating within a tolerance of only ±1% over the entire width of the machine

- ESpecially developed stored program control system for maximum ease of operation

Chocolate Cooling Tunnel

FeaturesThe enrobers are suitable to enrobe chocolate, cocoline, barrier and caramel processing.

- Available for machine widths from 1000 to 1500 mm

- The cooling tunnels are of modular design and consist of individual sections

- Energy saving and CFC-free insulation

- Stainless stell hoods that can be lifted on either side, for maximum accessibility of cleaning

- Cooling units contain a built-in semi hermetic air-cooled or water-cooled compressor, a recirculation fan and an evaporator as standard

- Cooling compressor housing also designed for easy cleaning

- Photo-pneumatic belt-tracking devices on both sides

External / Internal Decoration Device

It is a general purpose universal decoration device. It is designed to create a linear decoration in zigzag or circular forms on the surface of products such as wafer, chocolate, caramel based bars, as well as cakes, biscuits, candies, etc.

Thanks to the interchangeable and multi-nozzle head, thin / thick patterns and dense / sparse patterns can be obtained.

Granular Pouring Device

It is a general purpose granule scattering system. It is used to smoothly pour various dried nut particles onto products that are still covered with wet material. Granular material is poured from the funnel-shaped hopper onto the movable PVC band. The tape, on the other hand, allows particles to be poured onto the product surface in the form of a curtain. The device is made of stainless and food grade materials. It is manufactured in accordance with cooling tunnels with a PVC band width of 1000-1500 mm.

Granule Feedback Bands

Some of the granular materials necessarily remain on the surface of the PVC tape. In order to reuse this material, it is necessary to transport it from the exit of the cooling tunnel to the chamber. This task is done by granular feedback bands.