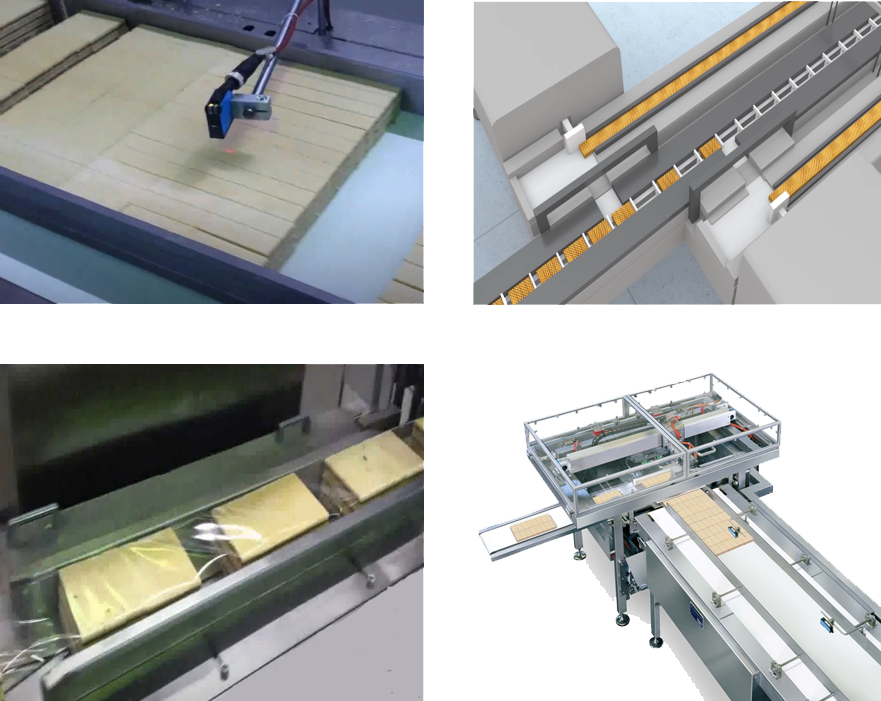

Row Distribution Systems

Features

- Speed up to 90 rows per minute.

- Different width available to suit customers’ needs (from 600 mm to 1500 mm)

- AC or fully Servo driven models available

- Automatic belt tracking system

- Pneumatic belt tensioning system

- Scraping device with collecting trays for crumbs or debris

- Electro-welded painted structure with floor levelling devices

- Transparent polycarbonate safety guard doors

- All parts in contact with the products are in stainless steel AISI 304

- Easy conveyor belt replacement

- Extractable transverse conveyor option for easy cleaning operations

- Highly customized solutions for difficult products (cereal bars, small pralines, bite size enrobed wafers.)

Multipack Wafer (Hoşbeş Type) Feeding System

Features

- Every multipack wafer feeding ünit has 90 stroks/min feed capacity

- Both AC and servo driven options is available

- Transparent polycarbonate safety guards

- All parts in contact with the products are in stainless steel AISI 304

- Scraping device with collecting trays for crumbs or debris

- Specific pusher and guide sets to the customer

Hihg Speed Wrapper

Features

- Fully servo driven electronic multi axis control for maximum precision at high speeds

- All parts in contact with the products are in stainless steel AISI 304.

- Four pairs of AISI grade steel fin wheels (including the bevel pair to fold the film) optimized to run also products of small dimensions.

- Hinged fin wheels assemblies with pneumatic lock. Interchangeable crimpers stops in open position

- Straight or Zigzag cutting knives in Cobalt based HSS steel

- Digitally controlled cut-off length.

- Double reel holder with pneumatic chuck provide enhanced film control for tighter packages.

- Mechanical/Automatic film centering system (web-guide) to allow correct unwinding of the reel in axis with the longitudinal sealing unit for high quality packaging process

- Automatic film splicing system

- Electronically controlled print registration with +/- correction

- High Pressure Air Reject for: splicing, empty, short product, not cut packs, not registered packs Codeprinter bracket and synchronization

- Outfeed product overhead belt/brush

- HMI Color OMRON 10” Touch Screen Operator’s friendly interface on swiveling arm.

- Suitable to run with all types of automatic distribution systems

- Integrated inline feeding system with vacuum unit – to pace products in the correct position at the insertion of the wrapper’s chain lug – a must – for high capacity productions.